Binary Distillation

Tags: Chemical Engineering

Model Continuous Distillation Equipment in the Industry as well as Flash & Batch Separation Processes in Binary Systems

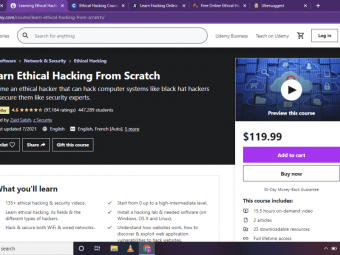

Last updated 2022-01-10 | 4.4

- Understand the Principles behind Binary Distillation- Design & Operate Flashing

- and Flash Drums via Flash Distillation of Binary Mixtures

- Understand and apply the principles and methods for simple distillation of binary mixtures

What you'll learn

* Requirements

* Mass Transfer Basics* Transport Phenomena

* Thermodynamics

* Mass and Energy Balances

* Physical Chemistry

Description

Introduction:

Binary Distillation is one of the most important Mass Transfer Operations used extensively in the Chemical industry.

Understanding the concept behind Gas-Gas, Liquid-Liquid and the Gas-Liquid mass transfer interaction will allow you to understand and model Distillation Columns, Flashes, Batch Distillator, Tray Columns and Packed column, etc...

We will cover:

REVIEW: Of Mass Transfer Basics (Equilibrium VLE Diagrams, Volatility, Raoult's Law, Azeotropes, etc..)

Distillation Theory

Application of Distillation in the Industry

Counter-Current Operation

Several equipment to Carry Gas-Liquid Operations

Bubble, Spray, Packed and Tray Column equipment

Flash Distillation & Flash Drums Design

Design & Operation of Tray Columns

Number of Ideal Stages: McCabe Thiele Method & Ponchon Savarit Method

Recycle

Condenser types: partial, total

Pressure drop due to trays

Design & Operation of Packed Columns

Pressure drop due to trays

Efficiency of Stages & Murphree's Efficency

Batch Distillation, the Raleigh Equation

Software Simulation for Absorption/Stripping Operations (ASPEN PLUS/HYSYS)

Solved-Problem Approach:

All theory is backed with exercises, solved problems, and proposed problems for homework/individual study.

At the end of the course:

You will be able to understand mass transfer mechanism and processes behind Binary Distillation in Flash, Continuous & Batch Processes. You will be able to continue with a Multi-Component Distillation, Reactive Distillation and Azeotropic Distillation as well as more Mass Transfer Unit Operation Courses and/or Separation Processes Course.

About your instructor:

I majored in Chemical Engineering with a minor in Industrial Engineering back in 2012.

I worked as a Process Design/Operation Engineer in INEOS Koln, mostly on the petrochemical area relating to naphtha treating. There I designed and modeled several processes relating separation of isopentane/pentane mixtures, catalytic reactors and separation processes such as distillation columns, flash separation devices and transportation of tank-trucks of product.

Who this course is for:

- Chemical Engineers refreshing their Mass Transfer and Separation Processes course

- Students on the relevant fields (chemical, mechanical, process engineering)

- Engineers working with Distillation Columns / Flash Drums

- Process Separation Engineer

Course content

5 sections • 77 lectures

This course includes:

This course includes: